The transformation of production is led by GreenCoLab with support from PROALGA—Associação Portuguesa de Produtores de Algas (PROALGA), coordinating life cycle analysis (LCA) studies and involving national companies Necton and Allmicroalgae.

The goal is to identify the environmental impacts of the sector in Portugal and implement technological improvements to make it more competitive on a European scale.

“We are identifying critical points in the process, which generate waste or consume too much energy, and acting on them with concrete solutions,” Joana Silva, PROALGA coordinator, states.

According to a press release, analyses revealed that the seaweed drying phase, essential for biomass preservation, is particularly energy-consuming, making it the current focus of optimization efforts.

“In response, more efficient techniques such as lyophilization and spray drying are being tested, and the possibility of eliminating steps like hydrolysis is being studied, as long as the final product quality is not compromised,” she adds.

Producers Necton and Allmicroalgae are also investing in systems utilizing solar energy and reusing water and residual carbon from their own industrial processes, significantly reducing the environmental footprint.

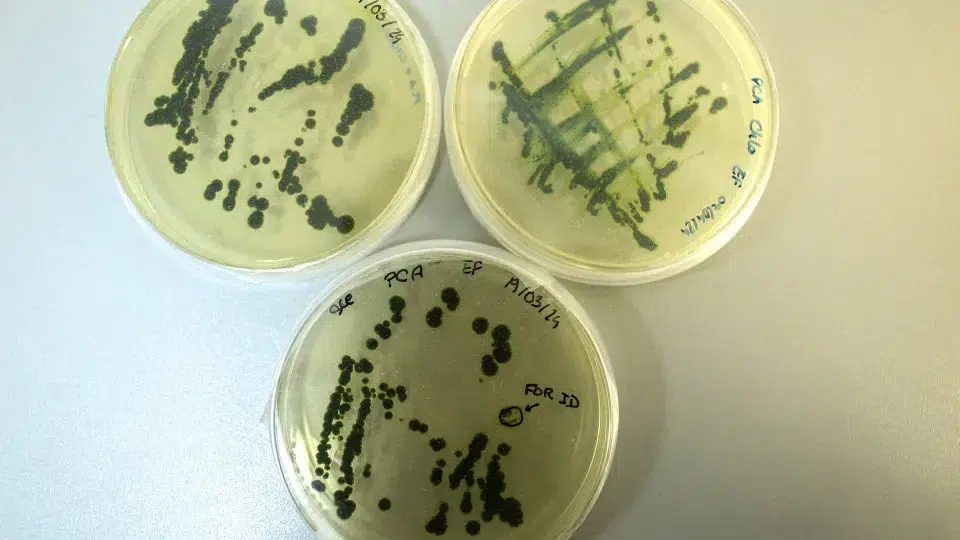

The biomass under study includes species like Chlorella Vulgaris, rich in proteins, vitamins, and lipids, which is already produced commercially in Portugal.

According to PROALGA, “when produced with good practices, Chlorella can have a lower environmental footprint compared to conventional animal protein sources like beef or plant sources like soy, as demonstrated by comparative studies.”